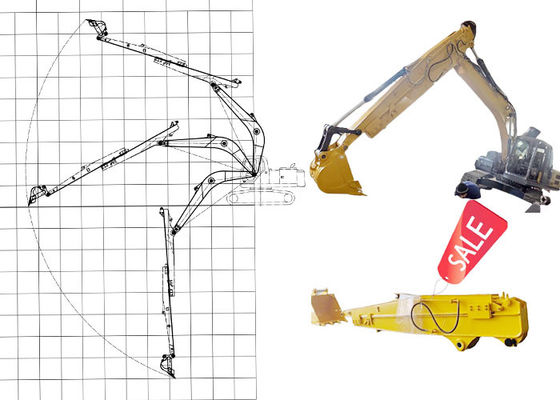

16m 18m Escavatore Telescopico Boom Telescopico Braccio Escavatore Long Reach Boom E Braccio Telescopico Con Scafo / Clamshell Scafo 1cbm 1.5cbm 2cbm

Applicazioni di lavoro idonee di un set di braccio telescopico per escavatore:scavare fondazioni di case, cassonetti, pozzi profondi, ecc.

Portata estesa:La progettazione telescopica consente un'estensione significativa, fornendo agli operatori una maggiore portata e flessibilità.e accedere a aree difficili da raggiungere senza la necessità di riposizionare l'escavatore.

Costruzione robusta:Realizzato con materiali di alta qualità, il nostro braccio telescopico è costruito per resistere alle condizioni più difficili.rendendolo una preziosa aggiunta alla vostra flotta di attrezzature.

-

Dimensioni compatte (3-5 metri):

- Ideale per scavatori più piccoli e spazi ristretti.

- Perfetto per progetti residenziali, paesaggistici e servizi pubblici.

- Fornisce un'eccellente manovrabilità mantenendo una portata adeguata.

-

Dimensioni standard (6-8 metri):

- Un'opzione versatile adatta per scavatori di medie dimensioni.

- Ottimo per lavori di costruzione in generale, scavo di trincee e scavo in aree più strette.

- L'equilibrio e la stabilità lo rendono una scelta popolare tra gli appaltatori.

-

Dimensione estesa (12-16 metri):

- Progettato per scavatori più grandi, offrendo una portata maggiore per scavare più a fondo.

- Eccellente per lavori di fondazione, costruzioni su larga scala e operazioni di dragaggio.

- Consente agli operatori di accedere a aree difficili da raggiungere senza spostare la macchina frequentemente.

-

Dimensioni pesanti (17-20 metri):

- Specificamente progettato per applicazioni pesanti e escavatori più grandi.

- Ideale per progetti industriali, movimenti di terra su larga scala e sviluppo di infrastrutture.

- Costruito con materiali rinforzati per gestire carichi e sollecitazioni significativi.

I dispositivi di fissaggio anteriori di una serie di escavatori a lunga portata e braccio telescopico possono essere:

* Clamshell Bucket * Standard Bucket

I dettagli di produzione di un set di braccio telescopico a lunga portata per escavatore a due sezioni sono i seguenti:

1. Progettazione

Il processo inizia con i nostri esperti ingegneri che utilizzano software avanzati per creare progetti precisi e funzionali.Ogni progetto è adattato per soddisfare le esigenze specifiche del cliente e gli standard del settoreOgni set di braccio telescopico di escavatore viene effettuato simulazioni multiple prima della produzione.

2. Taglio di piastre

Una volta completato il progetto, vengono selezionate piastre di acciaio di alta qualità.le piastre di un set di braccio telescopico per escavatore sono tagliate alle dimensioni esatte necessarie per il braccio telescopicoIl pannello di un set di braccio telescopico per escavatore viene tagliato da una macchina a plasma CNC con minore deformazione.

3. Lavorazione

Le piastre tagliate sono sottoposte a lavorazione per ottenere tolleranze precise.e superfici critiche per il montaggio e la funzionalità del braccioLa precisione di un set di braccio telescopico per escavatore è super alta.

4- E'un bello.

I bordi dei componenti lavorati sono bisellati per facilitare le giunzioni di saldatura forti.miglioramento della resistenza e dell'integrità complessive del braccio telescopico dell'escavatore finale.

5. piegare

Le piastre bisolate vengono poi piegate nelle forme desiderate utilizzando macchine di piegatura idrauliche.consentire di raggiungere la portata e la manovrabilità necessarie.

6. Saldatura

I componenti piegati vengono accuratamente saldati da tecnici qualificati.confezioni affidabili in grado di resistere alle sollecitazioni durante il funzionamentoLa saldatura è sotto stretta supervisione.

7. rilevamento difetti di saldatura

Dopo la saldatura, ogni giunto viene sottoposto a un rigoroso controllo dei difetti con metodi di prova non distruttivi.garantire la sicurezza e l'affidabilità del braccio telescopico per escavatore.

8E'noioso.

L'insieme saldato viene quindi perforato per ottenere dimensioni precise per il montaggio e il montaggio.Questo processo garantisce che il braccio telescopico telescopico per l'escavatore si allinea perfettamente con l'escavatore, massimizzando l'efficienza e la funzionalità.

9. lucidatura

Dopo aver borrato, la superficie del braccio viene lucidata per rimuovere eventuali imperfezioni e prepararla per la finitura.Questo passo non solo migliora l'estetica ma migliora anche la durata del braccio riducendo l'attrito e l'usura.

10- Tubi.

Successivamente, vengono installati tubi per i sistemi idraulici, che consentono un funzionamento senza soluzione di continuità del braccio telescopico.Critico per le prestazioni del braccio.

11- Pittura.

Il braccio telescopico viene poi rivestito con una vernice di alta qualità per proteggerlo dalla corrosione e dai danni ambientali.Questo tocco di finitura migliora la durata, dando al braccio un aspetto professionale.

12. Assemblaggio

Una volta verniciati, tutti i componenti vengono accuratamente assemblati, comprese le funzionalità aggiuntive come cilindri idraulici e accessori.garantire che ogni parte si adatti perfettamente e funzioni come previsto.

13. Prova

Prima di lasciare le nostre strutture, ogni braccio telescopico viene sottoposto a test approfonditi per verificare le sue prestazioni e affidabilità.Simuliamo le condizioni del mondo reale per garantire che il braccio soddisfi tutti gli standard operativi e le aspettative dei clienti.

14- Imballaggio.

Infine, il braccio telescopico viene confezionato in modo sicuro per la consegna.

Ulteriori dettagli di un set di escavatore a lungo raggio e braccio telescopico:

Ingegneria di precisione:Ogni componente è progettato con precisione, garantendo un'adattabilità e una funzionalità ottimali.che contribuiscono alle prestazioni generali e all'affidabilità del braccio.

Efficienza idraulica:Progettato per un'integrazione senza soluzione di continuità con i sistemi idraulici, il nostro braccio telescopico fornisce un controllo fluido e reattivo.migliorare la sicurezza e ridurre il rischio di danni alle strutture circostanti.

Dati di contatto:

Un grande sconto è in attesa!

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!